After revisiting the ongoing project of a crude home made thermionic valve or triode vacuum tube, I decided to dispense with the old Variac-controlled adjustable 60Hz power supplies. I made a new high voltage supply using a simple flyback converter topology, followed by a high voltage linear voltage regulator made from discrete components.

The low voltage supply is still 60Hz, but it is also followed with an adjustable regulator, in this case a LM350, a 3 amp device.

The high voltage is run through a Bogen T725, with a rotary switch selecting an output tap for audio output. This can be seen in the upper left corner. The low and high voltage supplies each have their own electrical cord so I don't have to use both at the same time. I suppose switches would have worked, too.

The power supplies got their first workout in an experiment to see if I could use a silicone rubber gasket in place of the usual RTV for sealing the glass envelope of the triode. It did not work well, but that is in part due to the irregular shape of the sealing surfaces. The filament's life was short and smoky, and I was unable to receive any signals. I completely rebuilt the regenerative radio set for these experiments, so I do hope I didn't miss-wire something. It could also be the fact that I'm attempting to use grid-leak biasing this time around, whereas in the old setup I used a separate variable bias supply for the grid (+/- 17Vdc IIRC).

Friday, December 5, 2014

Hysteresis/Induction Motor

This is something I built a while ago, but I wanted to describe it in some more detail. It is a simple alternating current motor that spins a thin disk of metal balanced on a sharpened point of graphite.

The circuit applied roughly equal current to each of the coils, phase shifted by 90 degrees. The large AC capacitor provides both phase shift and current limiting to one coil while the other is simply fed through a high wattage resistor. I strung together 12 smaller resistors in series/parallel and even attached heat sinks with thermal grease to get a suitable dissipation power and reasonable resistance of 17.5 ohms.

The two coils act together to produce a rotating magnetic field, as one always precedes the other by 90 degrees. Four coils would produce a much more symmetrical field, but two will do the job. As the steel mason jar lid is magnetized by the increasing field from L1, that part of the steel becomes attracted to the simultaneously falling field from L2, and gets pulled around toward L2. Much the same way, when a rising field near L2 magnetizes the steel that same part of the steel is repelled by the falling field from L1, and pushes the disc from L1 toward L2. This might not be all that is going on, but it suffices for me as an explanation of why this simple induction motor functions at all.

The circuit applied roughly equal current to each of the coils, phase shifted by 90 degrees. The large AC capacitor provides both phase shift and current limiting to one coil while the other is simply fed through a high wattage resistor. I strung together 12 smaller resistors in series/parallel and even attached heat sinks with thermal grease to get a suitable dissipation power and reasonable resistance of 17.5 ohms.

The two coils act together to produce a rotating magnetic field, as one always precedes the other by 90 degrees. Four coils would produce a much more symmetrical field, but two will do the job. As the steel mason jar lid is magnetized by the increasing field from L1, that part of the steel becomes attracted to the simultaneously falling field from L2, and gets pulled around toward L2. Much the same way, when a rising field near L2 magnetizes the steel that same part of the steel is repelled by the falling field from L1, and pushes the disc from L1 toward L2. This might not be all that is going on, but it suffices for me as an explanation of why this simple induction motor functions at all.

Saturday, November 30, 2013

Piezo-driven unstable carbon contact amplifier

This is my take on the "balance beam amplifier" from H.P. Friedrich's book, "Instruments of Amplification." This is essentially a relay mechanically biased to partway between on and off, with a soft contact material that varies its resistance with pressure: carbon. Way back in the day, circa 1910, such a device would have been driven electromagnetically. I attempted such a design a few years ago without much luck. This time around I happened upon the very good idea of using a piezoelectric disc in place of a more complicated set of coils and magnets. The efficiency of the disc is very high, and has a very high impedance which matches well to crystal radios made with high count litz wire. The only better possible driver would be a sound powered phone aka balanced armature speaker, and I may try that in the future for even better performance.

The most efficient piezo disc I could find at Radio Shack is the driving element in this design. A 100k resistor is connected to it in parallel, and any weak audio source (such as that from a robust crystal radio) is enough to drive it. I took pieces of the carbon rod from the center of a carbon-zinc ("Heavy Duty") D-cell battery to make the amplifying relay contacts. One piece is secured to the center of the piezo disc and the other is on the end of an adjustable balance arm. Counterweights on the other end of the arm adjust the resting pressure between the contacts.

Two D-cell batteries in series provide power - this runs to one carbon, across the unstable contact to the other carbon, through a 50 ohm winding on an audio transformer, and back to the battery. As the vibrations from the piezo disc vary the resistance between the carbons, the current through the transformer varies and is output from another winding to a sound powered phone.

This thing DEFINITELY amplifies! On a strong local station the output can be uncomfortably loud. Adjustment is very sensitive, and it often will take off in self-oscillation.

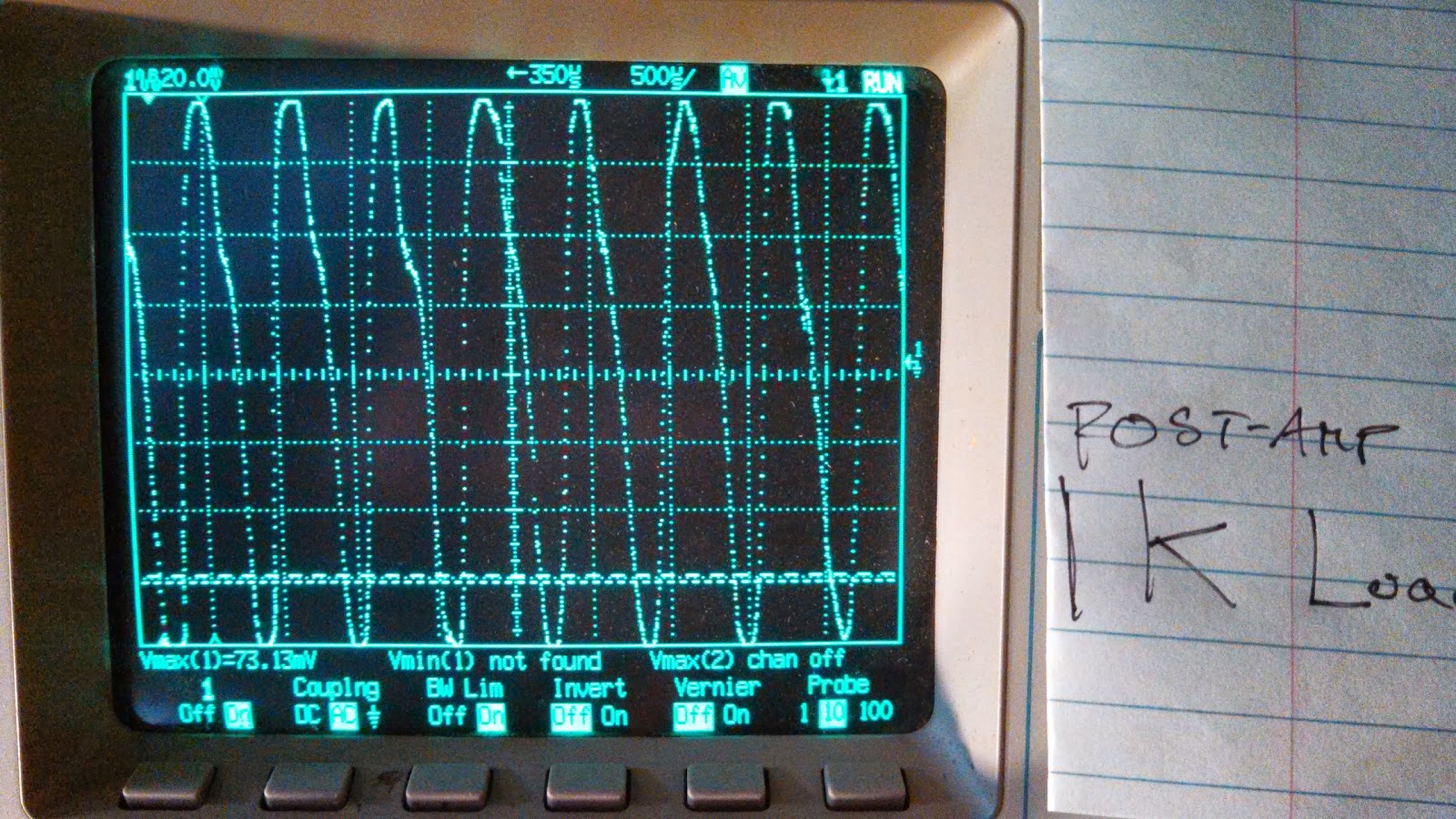

Here is an example of the amplification of a small audio signal. The first image is the audio source driving a 1k load, and the second is the amplifier driving a 1k load while fed by the same source.

It's not without added distortion, but the signal is amplified from about 80mVpp to 160mVpp.

Below are some images of the device itself. Not too pretty, but it works well and was made with only hand tools.

The current path includes the forward portion of the balance arm and would include the pivot itself if I did bridge it with some thin wire. I expect it would add noise and decrease amplification otherwise.

Below are some waveforms from this thing when it is self-oscillating. There was no input when these were taken.

The most efficient piezo disc I could find at Radio Shack is the driving element in this design. A 100k resistor is connected to it in parallel, and any weak audio source (such as that from a robust crystal radio) is enough to drive it. I took pieces of the carbon rod from the center of a carbon-zinc ("Heavy Duty") D-cell battery to make the amplifying relay contacts. One piece is secured to the center of the piezo disc and the other is on the end of an adjustable balance arm. Counterweights on the other end of the arm adjust the resting pressure between the contacts.

Two D-cell batteries in series provide power - this runs to one carbon, across the unstable contact to the other carbon, through a 50 ohm winding on an audio transformer, and back to the battery. As the vibrations from the piezo disc vary the resistance between the carbons, the current through the transformer varies and is output from another winding to a sound powered phone.

This thing DEFINITELY amplifies! On a strong local station the output can be uncomfortably loud. Adjustment is very sensitive, and it often will take off in self-oscillation.

Here is an example of the amplification of a small audio signal. The first image is the audio source driving a 1k load, and the second is the amplifier driving a 1k load while fed by the same source.

It's not without added distortion, but the signal is amplified from about 80mVpp to 160mVpp.

Below are some images of the device itself. Not too pretty, but it works well and was made with only hand tools.

The current path includes the forward portion of the balance arm and would include the pivot itself if I did bridge it with some thin wire. I expect it would add noise and decrease amplification otherwise.

Below are some waveforms from this thing when it is self-oscillating. There was no input when these were taken.

Completed Curve Tracer Circuit

Long overdue, the more or less final functional circuit of the curve tracer. The phase of the AC inputs is important so that the base bias is stable while the device under test receives power. I used separate transformers for each. R6/R7 is a potentiometer, as is R8/R9. Vvar is supplied by a variable linear regulator with low dropout.

I used TL712CP comparators for U2 and U1, and IIRC a LM833 dual opamp for U3 and U4.

Below is the circuit as thrown together.

It's not pretty, but it works reliably for any small BJT or FET. Outputs to the oscilloscope are posts on the right side - only the ground connection is clearly visible. The rocker switch at the top switches between PNP and NPN modes by converting U3 and U4 from inverting to noninverting unity amplifiers.

I used TL712CP comparators for U2 and U1, and IIRC a LM833 dual opamp for U3 and U4.

Below is the circuit as thrown together.

It's not pretty, but it works reliably for any small BJT or FET. Outputs to the oscilloscope are posts on the right side - only the ground connection is clearly visible. The rocker switch at the top switches between PNP and NPN modes by converting U3 and U4 from inverting to noninverting unity amplifiers.

Monday, August 26, 2013

The Curve Tracer is Functional

After continuing to ponder why the analog circuit was not functioning, I decided to play with it a bit more. I found one wrong connection and added a schmitt trigger input to the reset comparator.

The results are encouraging. Obviously it needs some refinement. But this curve set is unmistakable as that of a NPN. The ugly drooping of the collector-emitter bias is likely due to the high output impedance and poor voltage regulation of the passive supply. A voltage follower might solve this issue.

I also redesigned the part that supplies collector current, and thought about how to use it for PNP devices, though my first idea is wrong. The schematic below reflects these changes, including the wrong idea.

After more fiddling around, and some more circuit changes I started to get nicer plots like this:

It looks like I have base bias stability problem. More tinkering on this is sure to come.

The results are encouraging. Obviously it needs some refinement. But this curve set is unmistakable as that of a NPN. The ugly drooping of the collector-emitter bias is likely due to the high output impedance and poor voltage regulation of the passive supply. A voltage follower might solve this issue.

I also redesigned the part that supplies collector current, and thought about how to use it for PNP devices, though my first idea is wrong. The schematic below reflects these changes, including the wrong idea.

After more fiddling around, and some more circuit changes I started to get nicer plots like this:

It looks like I have base bias stability problem. More tinkering on this is sure to come.

Thursday, August 22, 2013

Steps!

So the previous efforts with etching payed off. The circuit works as planned, and while the intervals aren't quite as even as I was hoping, it should be easy to correct with resistor substitution. See below for a scope shot of the ramp output of the summing network and the buffered square waves feeding the decade counter.

Next step is to feed it through an amp with gain variable from 1 to 3 or so, and then a voltage follower, and then I'll really have something.

Next step is to feed it through an amp with gain variable from 1 to 3 or so, and then a voltage follower, and then I'll really have something.

Wednesday, August 21, 2013

I think I need a better curve tracer..

While it has been enlightening to look at some basic I-V curves of two-terminal devices, to ease my experimentation with home made transistors I need something that will step the signal to the third terminal. In the case of cuprous oxide or point-contact transistors this takes the form of a stepped current, and if I do as planned and experiment with crude thin film field effect transistors it would be a stepped voltage.

Even though there are cheaply available commercial solutions, I want to build it myself, of course.

And since I'm really perverse, I'll be relying on analog techniques.

My first go at a design was through using LTSpice, but I have not yet been able get it to work as it does in the simulations. Big Surprise, right? It's certainly not the first time I've been misled by circuit simulators.

The above circuit seemed like a reasonable way to go about things. I use a voltage doubler to create a current pulse once per cycle timed to coincide with the middle of a flat portion of the stepped ramp applied to the base of the device under test - DUT, or Q4 in the schematic. The ramp is generated by the interesting configuration of Q2 and Q1, which are fed by square waves from the comparator U2, buffered by Q3. The basic idea is that one cycle of the square wave, via C2, charges C1 through Q1. This turns on Q2 which reinforces the original voltage on the base of Q1. In theory it should remain steady until another pulse arrives through C2, stepping the voltage higher until the comparator U3 triggers, turning on M2 and shorting the base of Q1 to ground, discharging both C1 and C4, resetting the circuit for another accumulation. In practice the circuit proved very unstable, either ramping up and not discharging, or else discharging and not ramping up. There was a critical setting of R6/R7 that allowed repeated ramping, but there was a varying dead time between each ramp, and it is neccesary to be able to control both the peak ramp voltage and step interval over a wide range.

I've tried to duplicate the problem behavior in simulation, but have been unable so far. The circuit as built, minus the 5V regulator:

I decided a little breakout board for a 16 pin surface mount (SOIC) chip would make a fine test of my ability to create usable single sided PCBs at home. The results were excellent! This is way easier than messing with heat transfers of toner and ferric chloride. Plus, the etchant takes on a lovely emerald green color. Supposedly this mix will not have to be discarded; it can be rejuvenated by re-oxygenation by bubbling air through it or adding more H2O2. A capful of muriatic acid may eventually be needed, says the internet, but only if that pretty green color can't be achieved through oxygenation.

I suppose even the most extreme radical fundamentalist homebrew electronics devotees such as myself can get dragged into the future. All the traces came out fine on the above board, which is my first ever home-built circuit to use surface mount chips. As you can see, I don't currently have a stock of surface mount resistors, but that will change soon as this first attempt went so well for the SOICs. That 5V regulator missing from the previous circuit can be seen attached to this one. Also seen is the oddity of a DIP being attached as if it were a SOIC. Too think of how much more time it takes me to assemble circuits dead-bug style, or Manhattan style, or ugly style, or on perf board, when compared to how fast I made this PCB and how easily these chips when on.. ..and I was already not feeling very well today. If I were to drill a few strategic vias before etching I could even do this for 2 sided boards without much added difficulty.

Even though there are cheaply available commercial solutions, I want to build it myself, of course.

And since I'm really perverse, I'll be relying on analog techniques.

My first go at a design was through using LTSpice, but I have not yet been able get it to work as it does in the simulations. Big Surprise, right? It's certainly not the first time I've been misled by circuit simulators.

|

| It works just fine for a variety of different step intervals and step numbers, in simulation. |

I've tried to duplicate the problem behavior in simulation, but have been unable so far. The circuit as built, minus the 5V regulator:

|

| This was a test of two methods new for me: hand drawing with a sharpie marker, and using 1:1 31% HCL and 3% H2O2, or muriatic acid from a hardware store and hydrogen peroxide from a drugstore. |

|

| Freshly etched bare board. |

| |

| half populated next attempt at stepped ramp generator for curve tracer |

Subscribe to:

Posts (Atom)